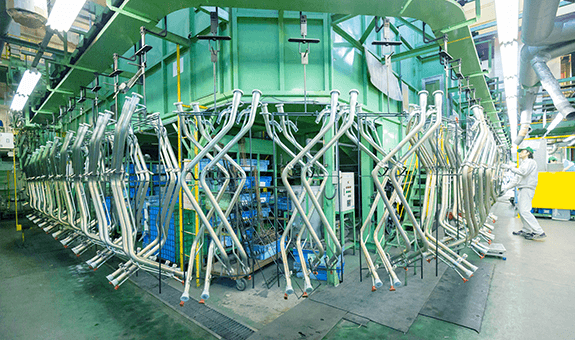

Surface treatment

The company was founded on electroplating, and today has decades of experience and expertise in electroplating and other surface treatment technologies. In addition to electroplating of zinc-nickel alloys, we offer the full array of surface treatment including Cosmer treatment and cathodic electrodeposition to improve corrosion resistance. Diverse surface treatments for a range of materials including steels, aluminum, and stainless steels means we can offer customers the optimal solution for their unique requirements. We successfully achieved volume production of stainless-steel fuel filler pipes with cathodic electrodeposition.

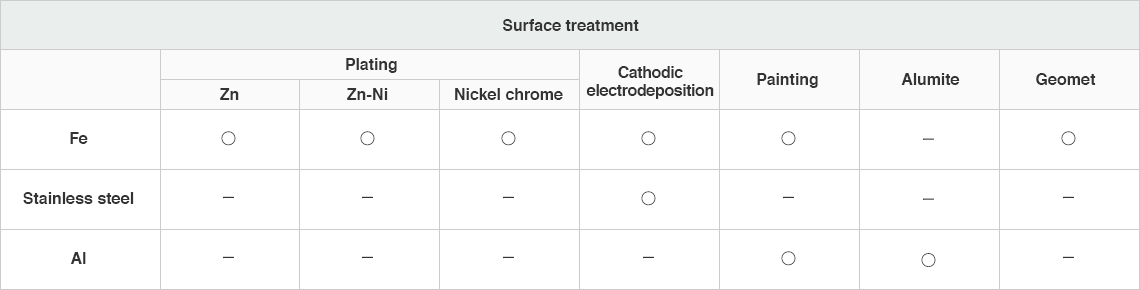

We have volume-production expertise in the following combinations:

There are many firms that specialize in electroplating, or painting, but there aren’t very many like us who are experts in both plating and cathodic electrodeposition. And in addition to simply processing the outside of a pipe, for example, we can also plate or paint the inside, and handle work up to 2 meters in length, or incredibly small. We can mask areas that can’t be painted, and have a wealth of other technologies to meet your requirements. We use environment-friendly chemicals, conserve energy, and work to improve our surface treatment technologies constantly.