Development and test, mold and equipment manufacture

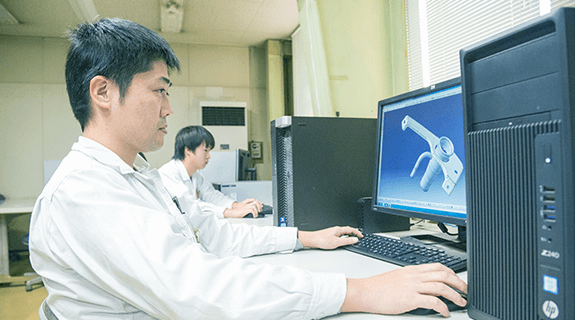

To produce the products that accurately meet customer requirements, our design engineers work closely with customers. Frequent discussion ensures that we fulfill requirements for specifications, functionality, durability, etc., but the designers also work closely with manufacturing to ensure that the products will be easy to manufacture.

We design and develop the parts needed for the vehicles planned for several years in the future, but are also involved in R&D into the parts needed for the cars of the future. Our ideas are picked up by the automobile majors, such as switching the fuel filler pipe from ordinary steel to stainless steel and using cathodic electroplating to improve durability when automobiles in the United States needed to extend the warranty from 12 to 15 years. We are also investigating new materials to replace conventional steels, working to reduce component weight in hybrid, fuel-cell, and electric vehicles. In more and more cases, we are leveraging our core technologies and accumulated expertise to proactively meet and exceed customer requirements.

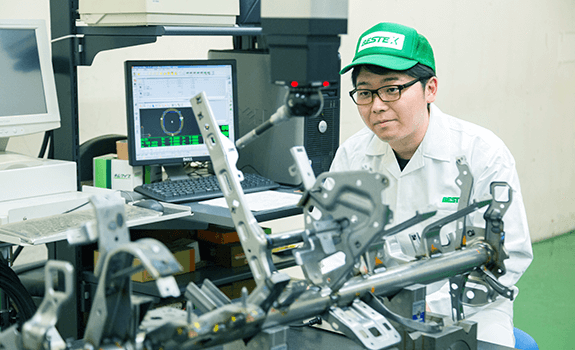

The research wing at the Ojima Plant handles vibration testing, load fatigue checks, strength analysis using computer aided engineering (CAE) software, and more, supporting the development of products that fulfill customer requirements.

and equipment to handle diverse manufacturing techniques

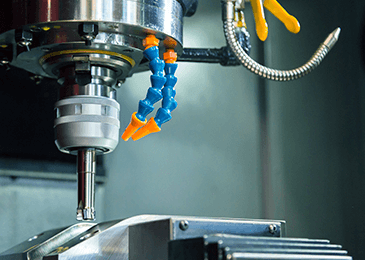

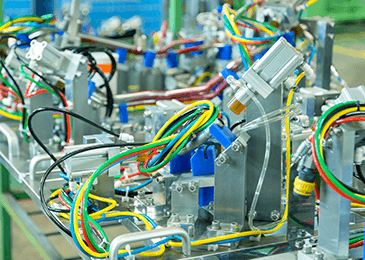

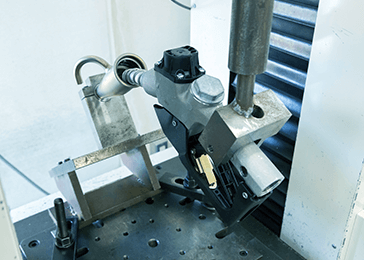

Stamping, pipe manufacturing, and other work is performed on a wide range of material, including ordinary steels, stainless steels, and aluminum. We design and make the molds, tools, and equipment required ourselves, ensuring performance to match the material characteristics and required specifications.

Steering hanger beams, one of our major products, require a large number of components be attached to the fabricated pipe, and our unique expertise takes the effects of welding heat into account to provide assured precision.