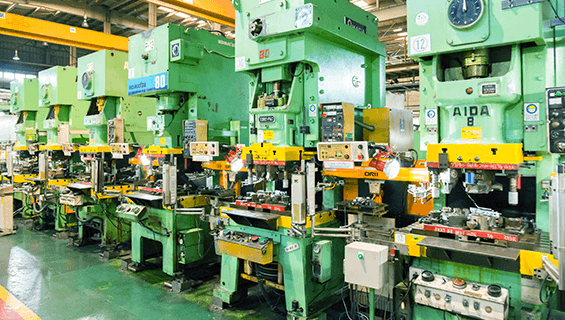

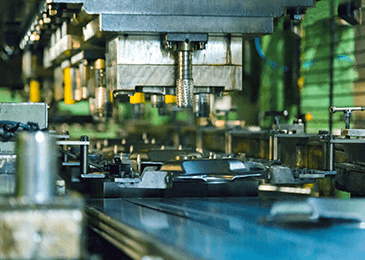

Stamping and pipe manufacturing

Different products demand different sheet shapes and thicknesses, and we select the optimal equipment and techniques for each job: presses with capacities from 60 to 500 tons, loaders, transfer robots, tandem line pacers, and more. We can handle steel sheets from very thin 0.6 mm to thick and heavy 4.0 mm.

To better meet customer needs, we have constructed unattended fabrication lines utilizing industrial robots to handle a wide range of processes. They handle pipe diameters of 4.76 to 72 mm, for a range of materials including ordinary steel as well as stainless steel and aluminum for improved corrosion resistance and lightness. Our pipe fabrication technology provides corrosion resistance and durability far beyond conventional approaches, playing an important part in extending vehicle service life.

In a Honda 4WD vehicle a center-mounted fuel tank was required to increase cabin space, and as a result the fuel filler pipe (connecting the fuel filler inlet to the fuel tank) had to be routed through a longer, more complex path. While this is extremely difficult for other firms to handle, our technology provided the solution, and today our fuel filler pipes are a major product for the company, used in almost all Honda models.

Many of the products we make have complex shapes, or unusual sizes, and cannot be manufactured on general-purpose equipment. We design and build our own manufacturing equipment to handle product requirements, such as pipe expanders and screw molders. Equipment created here at the head office plant is shipped to our production facilities overseas, ensuring that they can match the high quality of products manufactured in Japan.